Did you know that as much as 70% of meat and vegetable trimmings waste is avoidable? Winnow’s data reveals that there is an untapped opportunity within commercial kitchens to increase product yield by reducing trimmings waste. Through insights surfaced by Winnow’s artificial intelligence (AI) tool, Winnow Vision, kitchens can reduce food purchasing costs by an additional 0.5-1%.

There is an untapped opportunity within trimmings waste to reduce food costs. This blog reveals the 3 ways to increase your product yield that help to cut costs while upskilling your team.

Trimmings waste - sometimes referred to simply as cuttings - is often considered unavoidable. Yet images from Winnow Vision reveal that this is not the case. By reducing this waste stream, kitchens are able to:

- Maximise product yield by identifying team training needs

- Repurpose high value ingredients

- Manage inventory more effectively with more visibility

Kitchens can already save between 3-8% of food cost by optimizing production and reducing overproduction. Trimmings is an additional savings opportunity that kitchens can benefit from.

How does Winnow track trimmings waste?

Winnow’s AI can recognise 65 unique trimmings items that include fruit and vegetable trimmings, meat and fish, and bakery items. As trimmings are discarded into the bin - often in a preparation area or separate kitchen - a photo is captured for each recording event.

These images reveal where there are opportunities in the kitchen to increase product yield. They can spark creative ideas around repurposing certain ingredients or dishes, or identify training needs within the team.

This can result in significant savings for a kitchen. For example, one hotel serving an à la carte menu is saving $7,000 annually by reducing avoidable trimmings. This figure could be much higher for operations serving buffets as well as a la carte menus.

These insights can be accessed by Winnow customers through Winnow’s analytics platform, Winnow Hub. The online Hub enables chefs to easily track every recording event by filtering for ‘Trimmings’ in the platform. These insights can then be shared with the team in a weekly team meeting.

Maximise product yield by identifying team training needs

A key benefit of looking at trimmings waste is identifying food preparation techniques that can be improved within your team.

By improving cutting techniques on certain ingredients, there is an opportunity to increase the yield in your kitchen. This may be on fruit and vegetable items, or within fish or meats.

Chefs are able to view images to identify where there are further opportunities for increasing product yield.

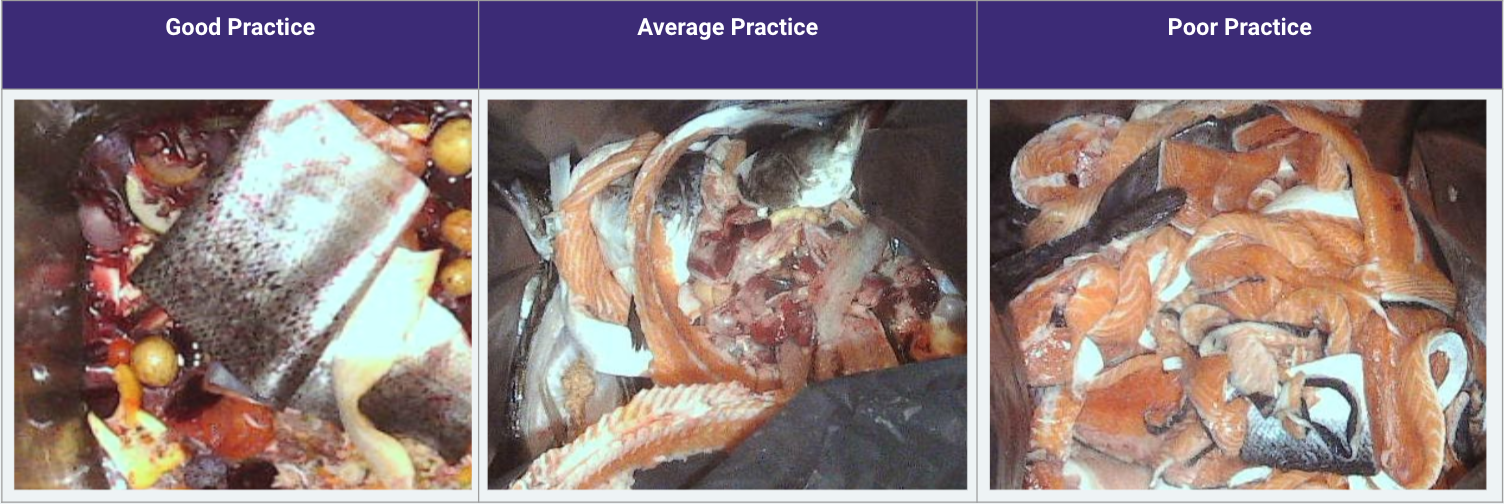

For example, the images below give an indication on good, average, and poor food preparation techniques:

As seen on the right hand ‘poor’ image, there is still a visible amount of salmon flesh that has not been removed in this preparation. By providing the right knife skills, teams can move from ‘poor’ to ‘good, and reduce the food costs of the kitchen.

Chef Matsuo from Hilton Tokyo Bay explains how images have helped to reduce trimmings:

“Thanks to the images we are receiving from Winnow, we have realised that we create quite a lot of unnecessary trimmings waste. We are now paying more attention to how we cut these to make sure we reduce unnecessary waste.”

Repurpose high value ingredients

Addressing meat and vegetable trimming waste not only cuts costs but also increases the yield of an ingredient. The kitchen needs to use less resources to provide the same number of dishes without compromising on quality.

For instance, items that were previously discarded can be repurposed and sold to increase profit margin.

If you find that an ingredient like leeks are your top trimmings waste item, what creative ways can you find to get more from it?

For instance, you can:

✔ Fry stalks and use like onions or spring onions

✔ Add to pesto or herb condiments

Finally, trimmings images can also reveal where kitchen inventory can be managed more efficiently.

If photos reveal that meat and vegetable trimming waste is high because ingredients are partly spoiled, then it may indicate that the inventory can be managed better.

This visibility is something that has not been easy to obtain for Head Chefs or Managers that are overseeing multiple kitchen operations.

Closing thoughts

Currently, trimmings waste is an undervalued part of a food waste reduction strategy. However, with potential reductions up to 1% of food purchasing costs, this is a significant area for culinary teams to consider.

In this challenging period for the hospitality industry, reducing food costs by up to 1% can be a significant help for every kitchen.

If you would like to learn more about how you can reduce product yield in your kitchen, sign up for a demo today.

Comment on my blog